ROLL 1400

ISO pallet 1000 x 1200

ROLL 1410

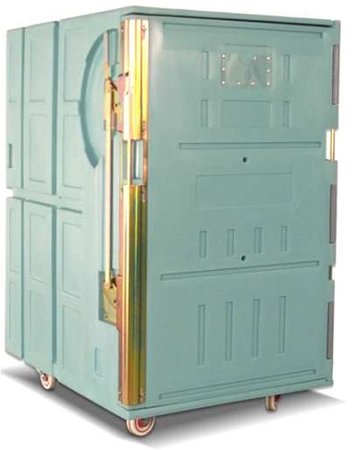

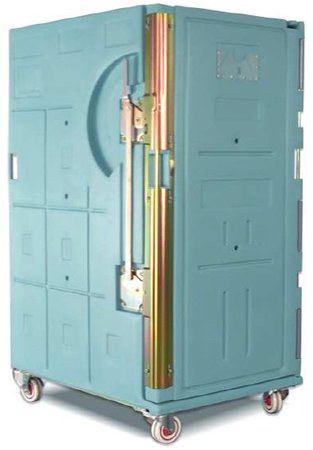

Double-wall rotomoulded PE/PU foam injection isothermal roll, a process in which Olivo is world leader. The one-piece structure ensures watertightness and avoids thermal bridges.

The inside of the box is grooved to create convection corridors to promote cold circulation.

Designed and manufactured in France

OLIVO factory is located in the heart of the Saint-Etienne region, upstream from the Gorges de la Loire. For over 65 years, factoty has been working to keep production facilities in Rouchonne, the cradle of plastics processing and industrial know-how.

Durability & maintenance

The rotational moulding process makes it easy to re-weld the material in the event of breakage. Regular maintenance and careful handling will extend the product’s useful life.

Know-how

Making an insulated container requires no fewer than 200 manual operations. These skills and techniques contribute to the quality and sturdiness of Olivo containers.

- One-piece rotational moulding. Grooved interior walls to encourage convection.

- Double-axis body/door articulation. 270° opening door

- Pelican” type 2-point quick-release fastener in zinc-plated, dichromate-coated steel

- EPDM seal in one-piece frame

- Recessed label holder

- 2 moulded-in, recessed handles

- Half-height door stop system for locking in open position

- 9 Ø 80 mm metal feet